Soft Goods

Soft Goods + Prototyping

I'm a passionate textile enthusiast and maker who thrives on hands-on creativity. Whether a soft goods project includes challenging requirements and/or a tooling budget, they consistently demand resilience in the quest for the perfect solution of assembling an array of 2-dimensional pieces purposefully to solve the puzzle.

I enjoy collaborating with clients and delving into crafting both low- and high-resolution mockups. These tangible representations not only help visualize possibilities but also encourage hands-on interaction for more thorough evaluation. These 3-dimensional sketches serve as invaluable tools in conveying intent to a manufacturer, conducting user testing, to use as a prop in a photoshoot or any other purpose you can imagine.

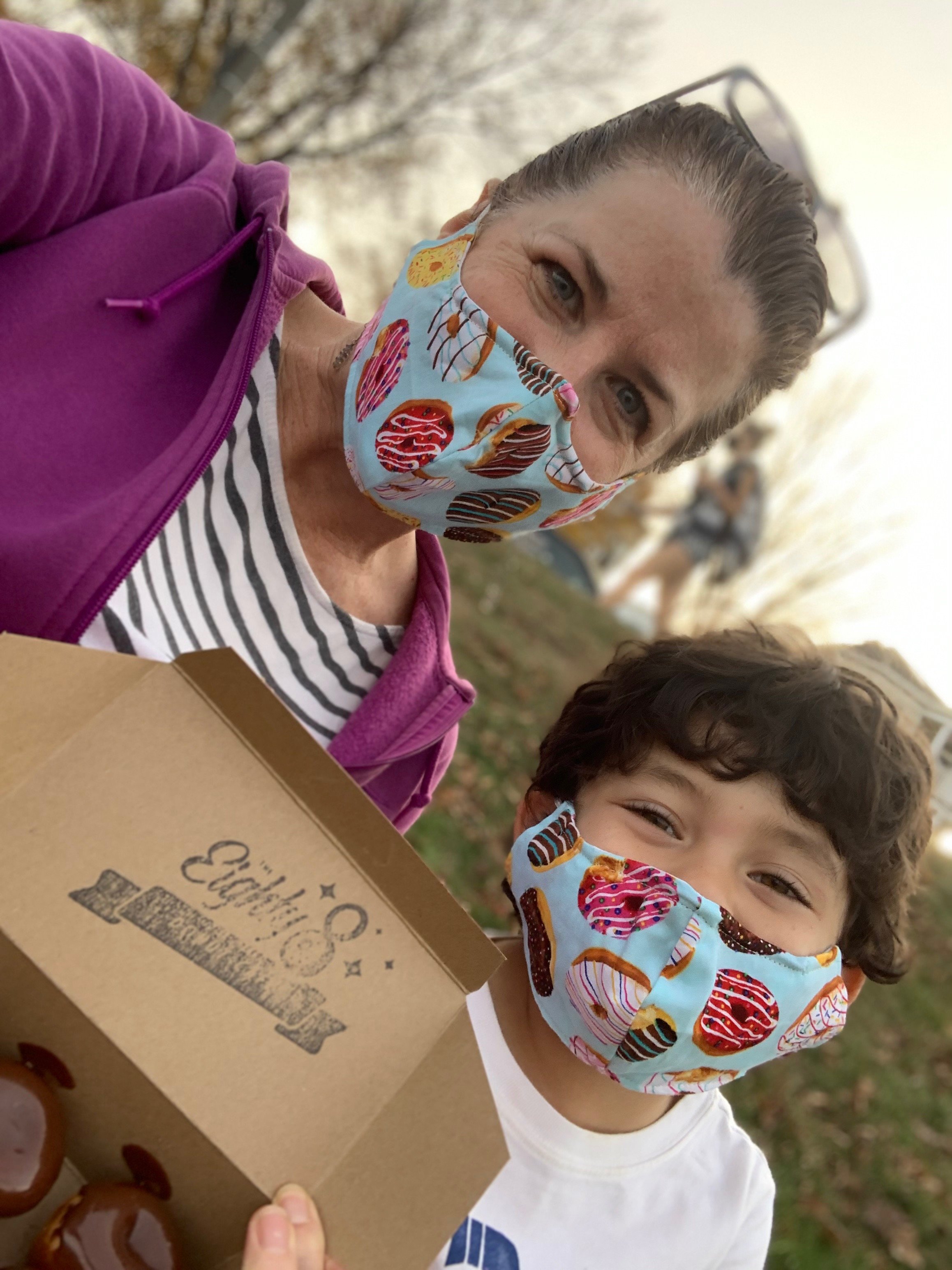

Hospital Isolation Gowns

In 2020, amidst the global pause of the pandemic, the spirit of makers around the world rose to the occasion, providing essential aid to hospitals, care centers, and individuals in need. I volunteered my sewing skills as part of a dedicated team of 45 sewists, aiming to alleviate some of the strain on healthcare facilities. To address the shortage of hospital isolation gowns, we repurposed surplus surgical drapes. Upon joining the effort, I discovered they were struggling with the absence of a predefined pattern for the project. My focus shifted to utilize my design and leadership skills, resulting in the creation of a pattern and sewing instructions. I collaborated with the hospital for approval and guided over 60 volunteers through three Zoom calls to ensure successful gown construction. Together, we produced 900 gowns, addressing the critical shortage exacerbated by supply chain issues. This experience left a lasting impression, showcasing the power of collective skills and goodwill to foster hope at a time when we all needed it most.

SMART Garment

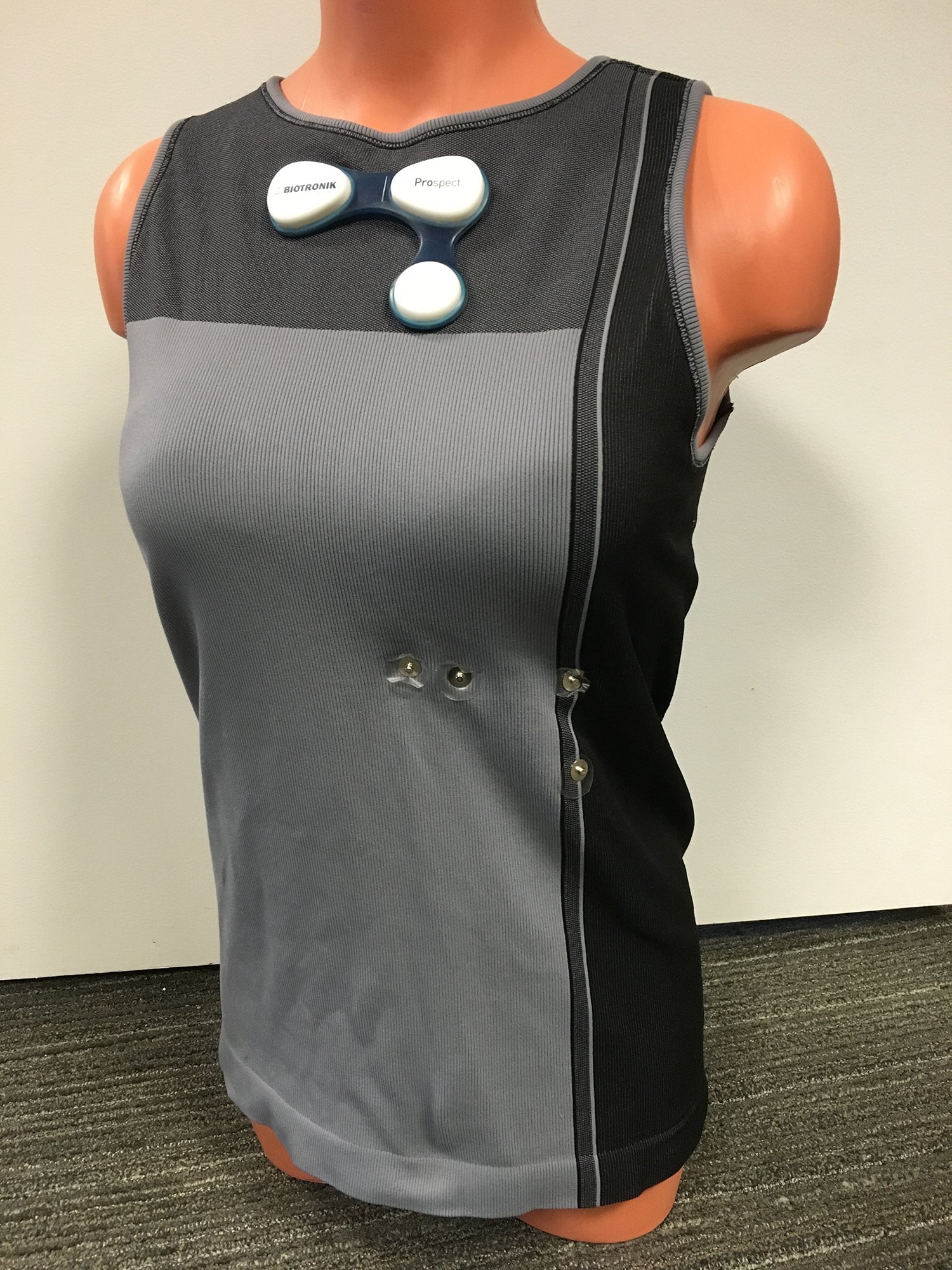

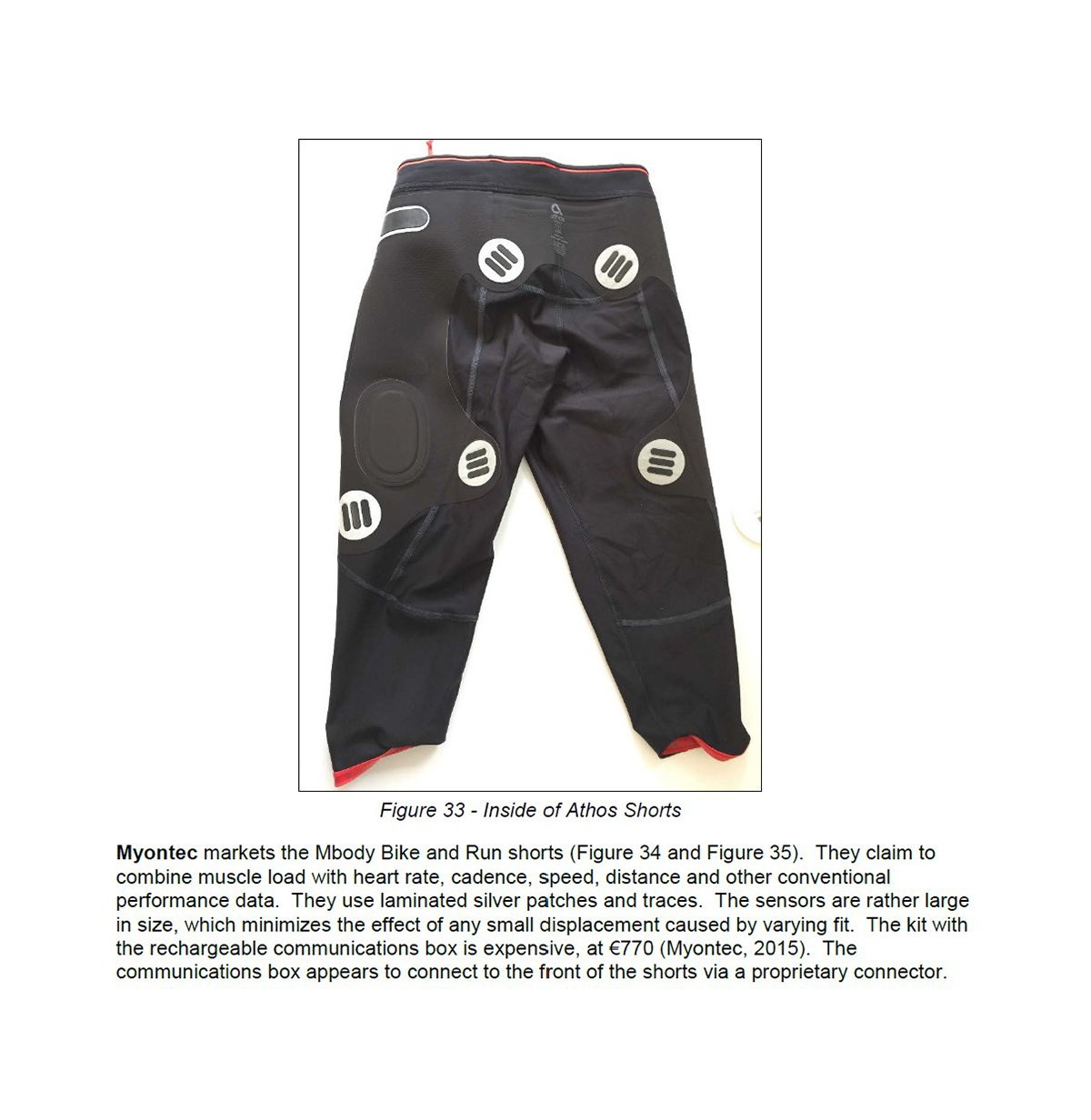

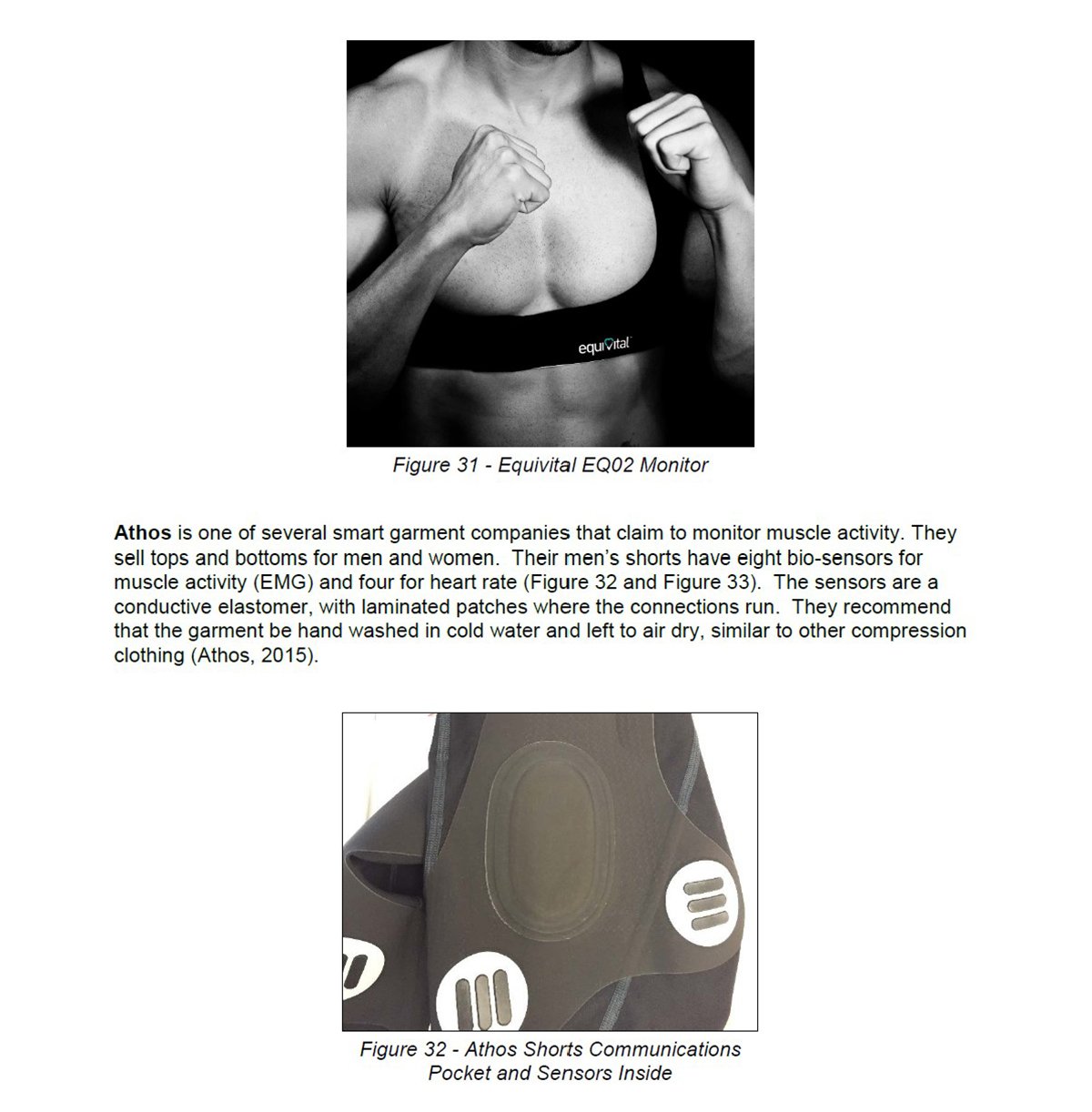

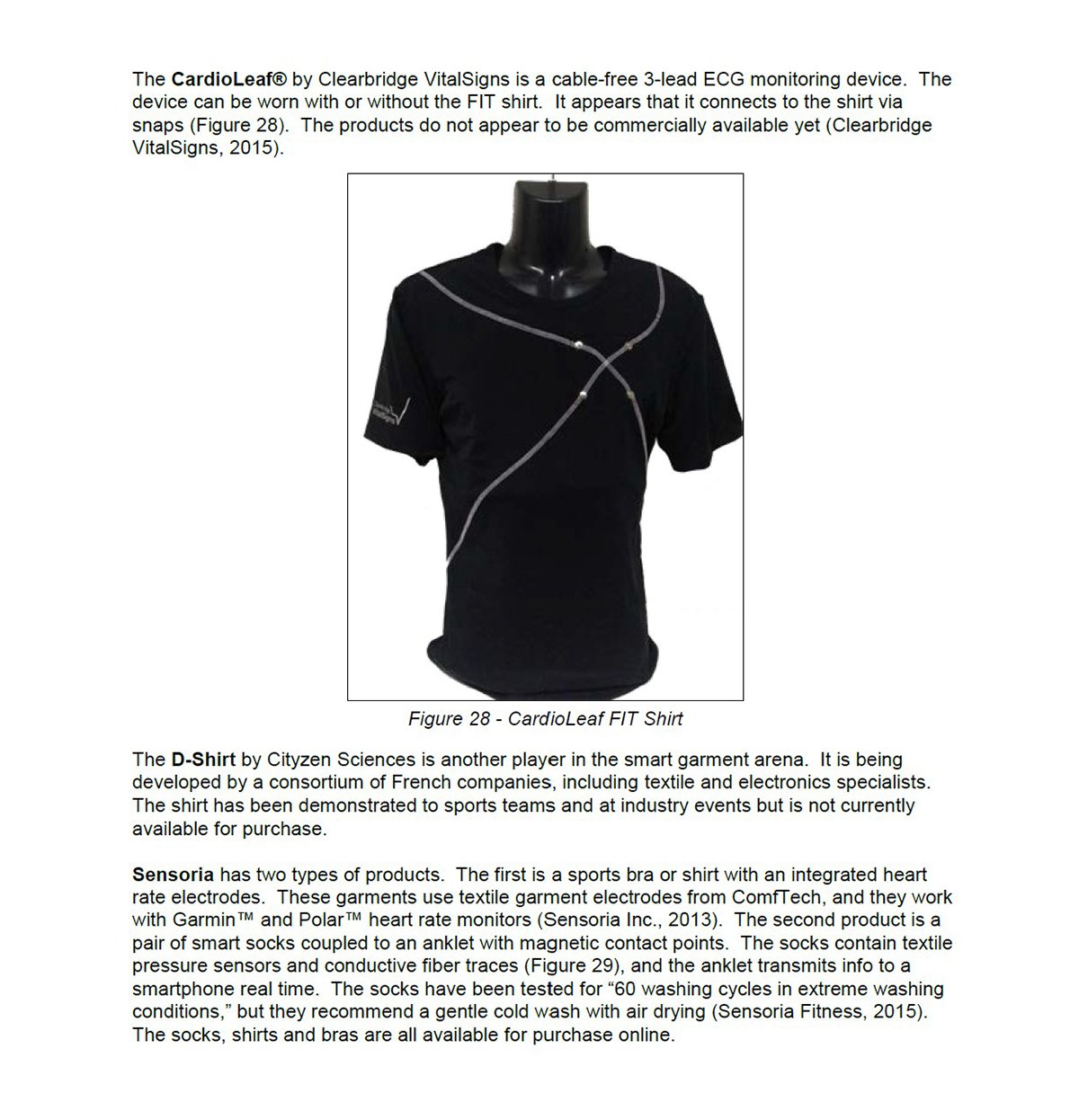

This project involved extensive exploration and research in technology. We delved deep into existing SMART components and textile-compatible circuit technology, aiming to develop solutions that were not only flexible and washable but also comfortable to wear during exercise. Our process included mocking up and testing circuits with various components and conductive elements to explore different configurations. Understanding body geometry, considering the range of sizes and accurate anatomical landmarks was critical for the proper placement of the sensor, ensuring compatibility with a wide variety of body types and sizes.

Manta Product Development extended an invitation to collaborate on conceptualizing a SMART garment featuring a heart rate sensor that seamlessly snapped onto a fitted garment for cardiac monitoring. The modular sensor eliminated the need for a separate heart rate monitor on a chest strap, and integrated the circuits directly into the fabric. Leveraging an existing tech garment enabled us to quickly prototype and test it in the lab and with users, gaining valuable insights into how and when they might integrate it into their lives. This user feedback played a pivotal role in shaping the next iteration of the garment.

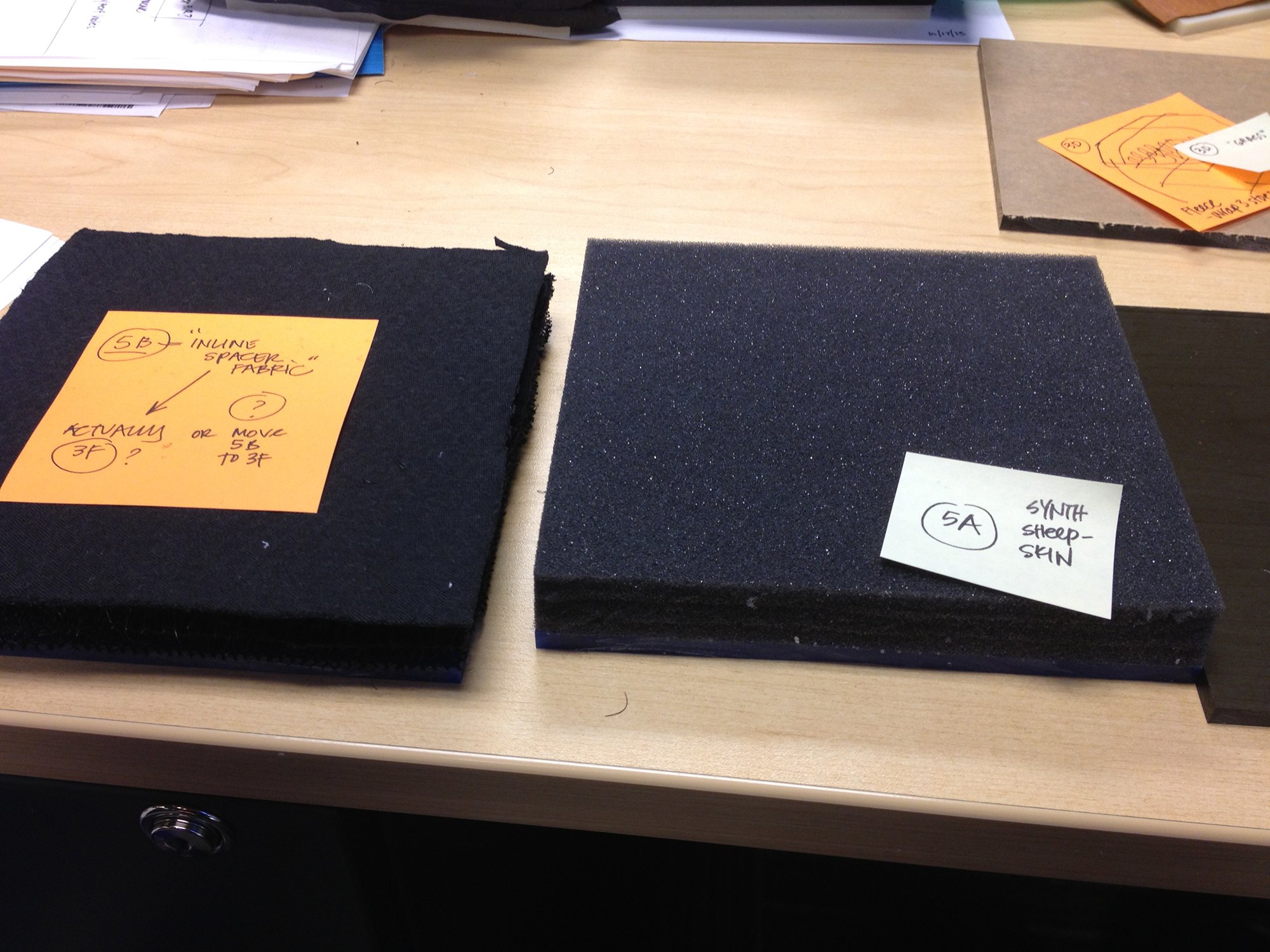

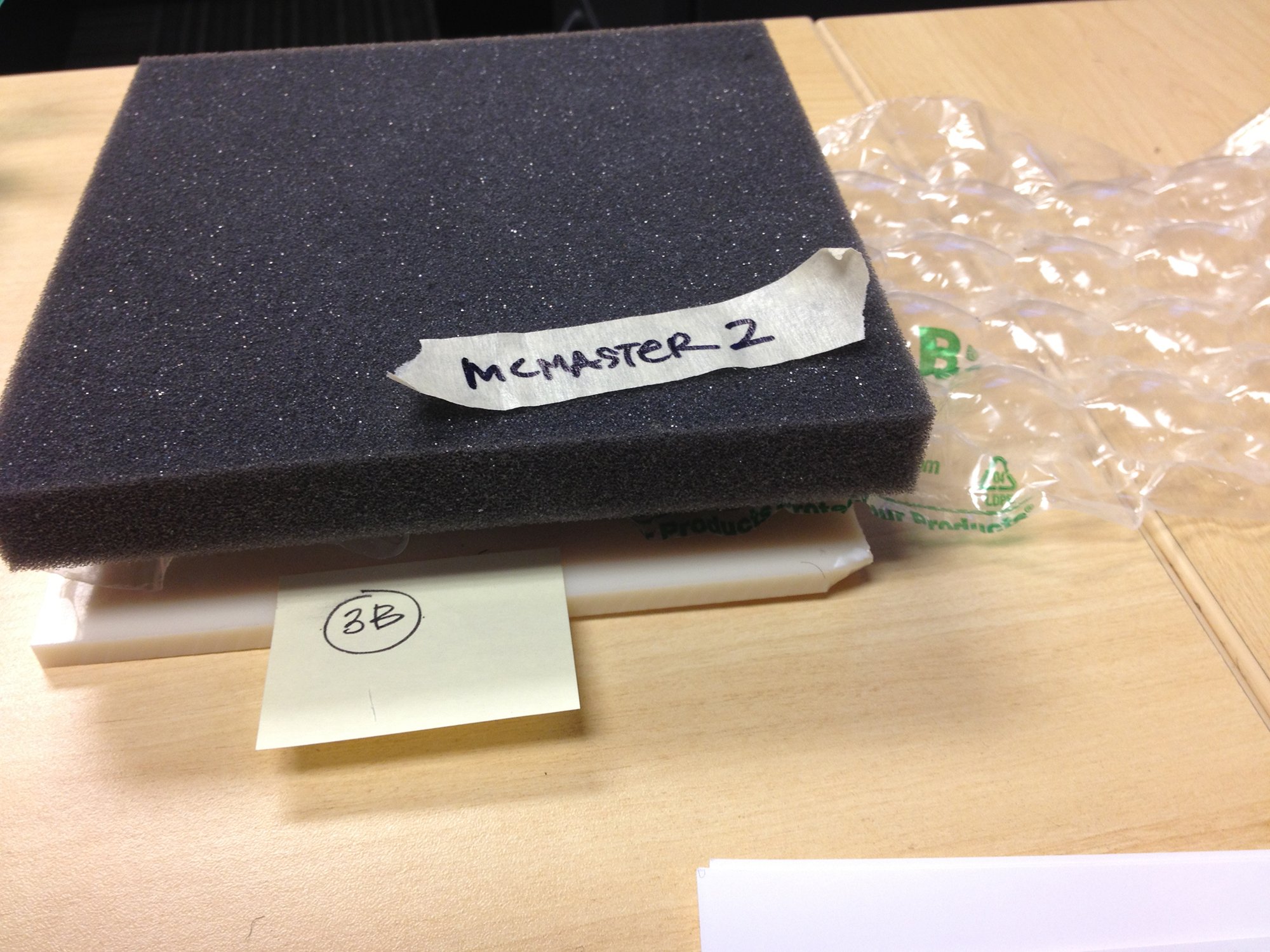

Materials Testing

The realm of textiles presents an expansive array of material possibilities for concept development. In collaboration with Manta Product Development, this project delved into the arrangement of diverse materials and components, such as air bladders or cooler packs, in stacks. The goal was to establish a repeatable method that enabled two layers of the stack to shift in a controlled manner, preventing skin damage to horses needed to wear a leg brace.

Our process involved creating mockups and rigorously testing the stacks to refine the options suitable for integration into the actual leg brace. Cycle testing was then conducted to gain insights into wear and assess the likelihood of skin abrasion over time.

Carrying Case Design

Conceptual exploration in soft goods products is anchored in user needs, project requirements, cost, materials, human factors and construction methods. Exploring each aspect individually and then in concert provides solutions that resonate. Working with a manufacturer at the outset ensures that the concept that is developed can be manufactured to meet the design intent defined by the product development team. Conversations flow , discoveries are made and iterations lead to the right solution based on best practices.

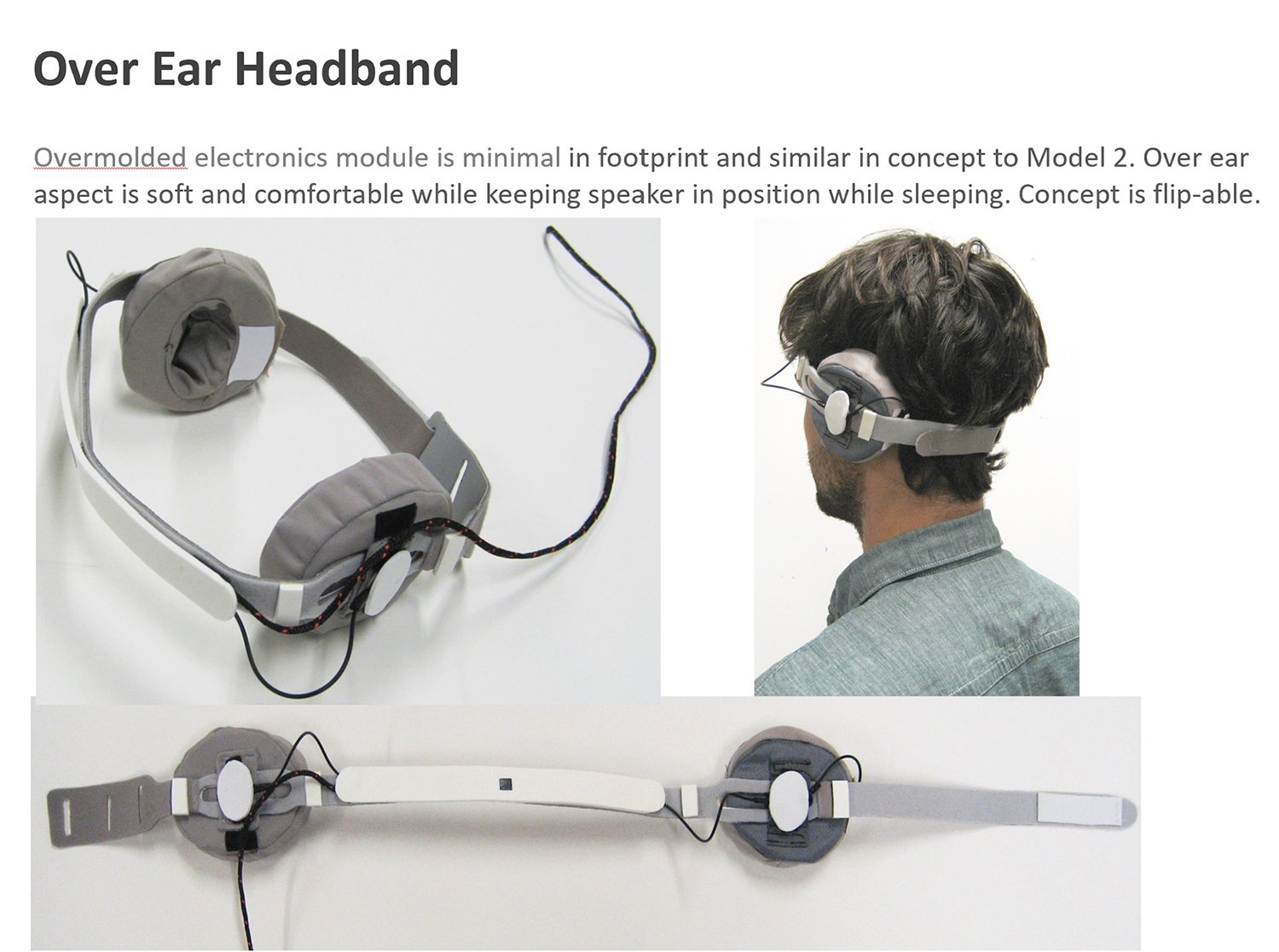

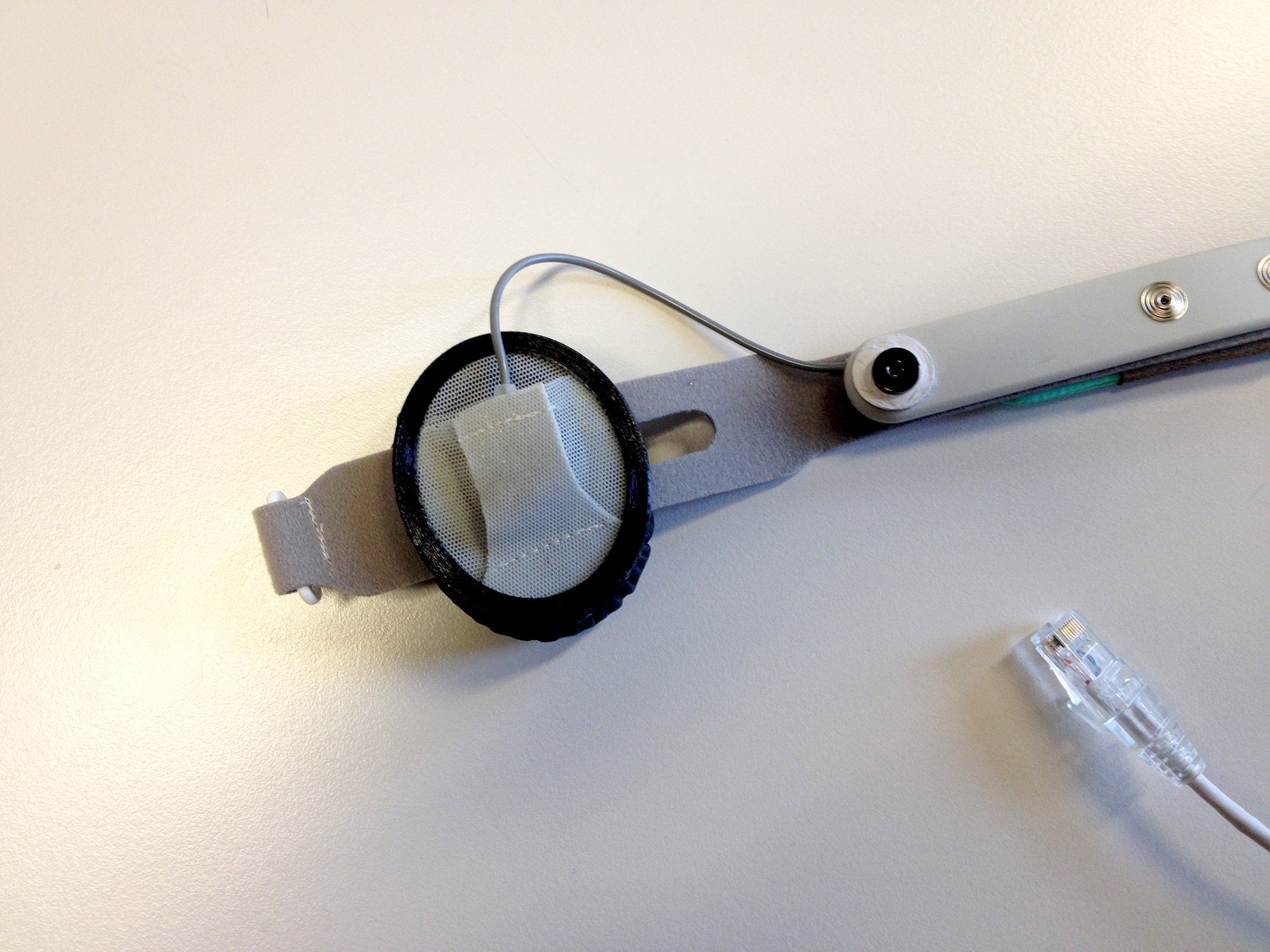

Working Prototypes

Product development efforts often require proof of concept models and/or models for photography. Plastic parts have a plethora of ways to fabricate prototype parts in low quantities for these efforts, but soft goods often require the finesse of hands on “maker” skills to get the fit and finish just right. As a tailor fits clothing to a person, designers with soft goods fabrication expertise often craft a pattern to make the fabric engage with a plastic assembly to create the look and feel of the production piece.

Visualizing soft goods solutions through the construction of mockups and prototypes is a service I offer to my clients. These tangible examples illustrate how soft materials can meet and potentially exceed product requirements. Opting for fabric solutions often means embracing a cost-effective, tooling-light approach that not only saves time and money but also results in lighter weight products with increased flexibility and collapsibility. These qualities contribute to reduced shipping volume and storage space while imparting a distinctive "soft" appearance to the final product, enhancing comfort for the end-user, and presenting unique value propositions. Through this hands-on approach, I am dedicated to helping clients realize their soft goods visions and achieve success in the competitive market by offering innovative and user-friendly solutions.

The collapsible travel product prototype shown above demonstrated the ability to store the product in a smaller space and compact it to be more efficient for travel.

The preliminary wearable prototypes shown below were built to demonstrate contour and fit to the human body as we conceptualized form opportunities optimizing molded and soft good parts, and then more finished prototypes were sewn and assembled for formative user testing to acquire user feedback.

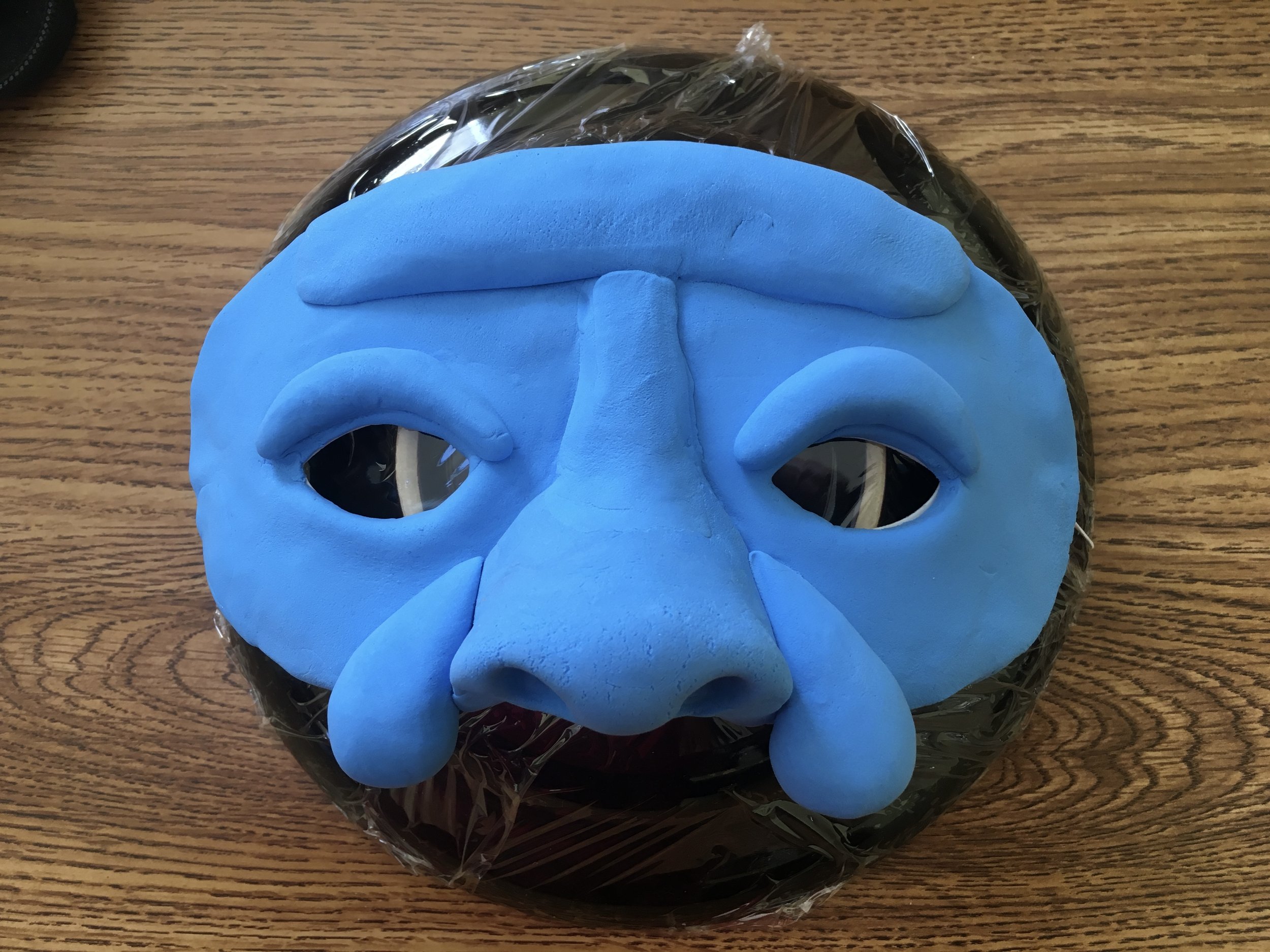

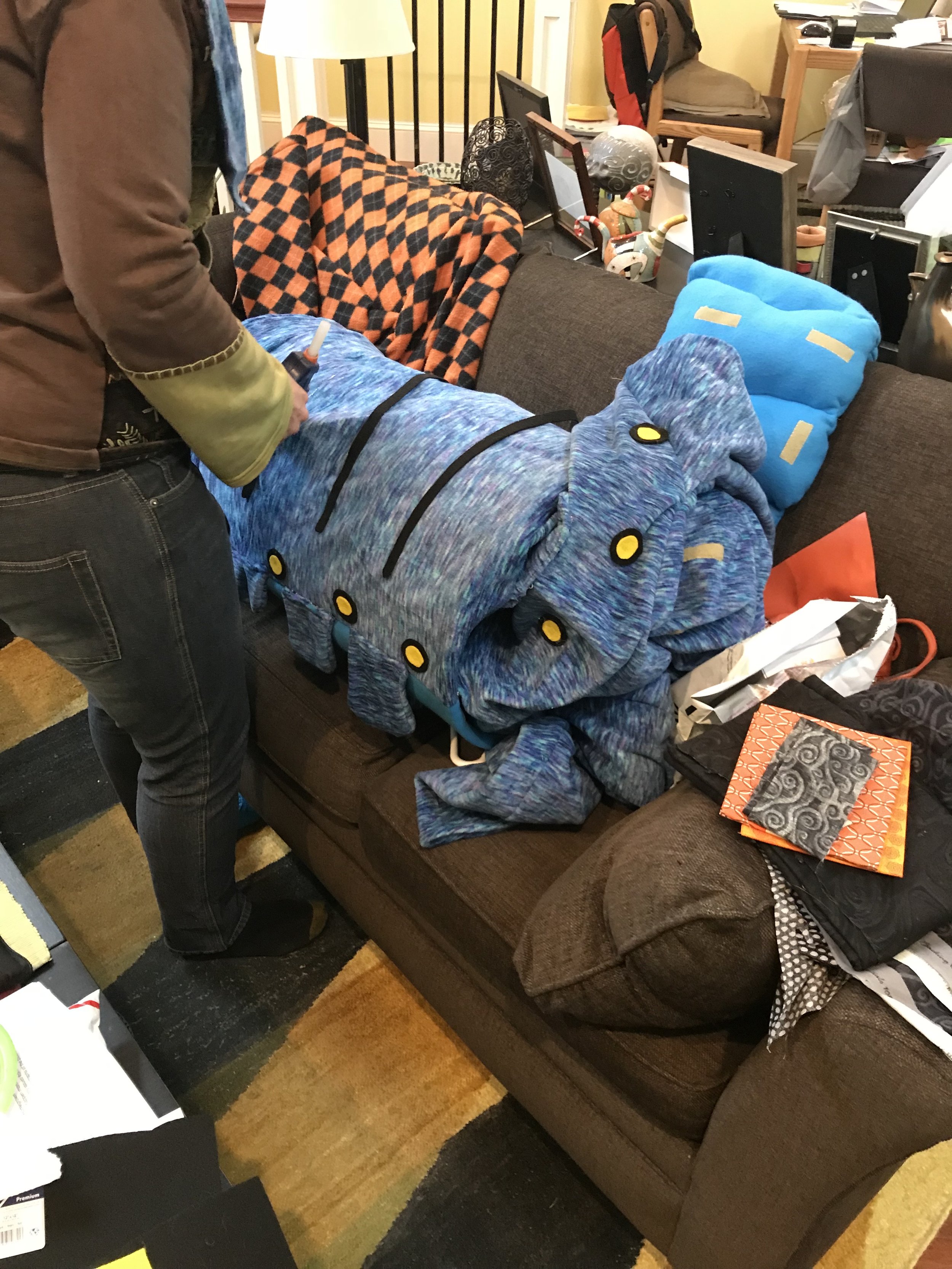

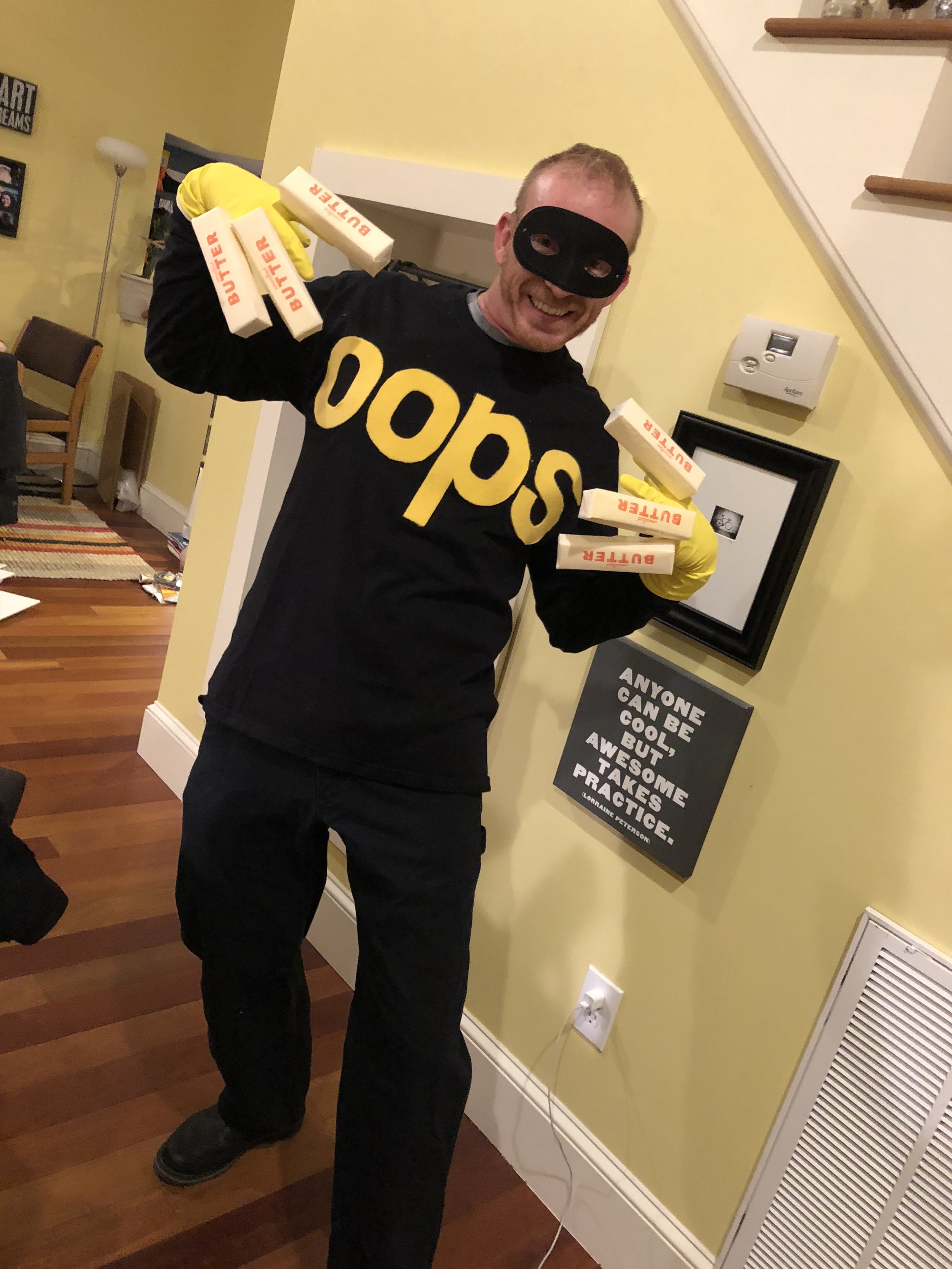

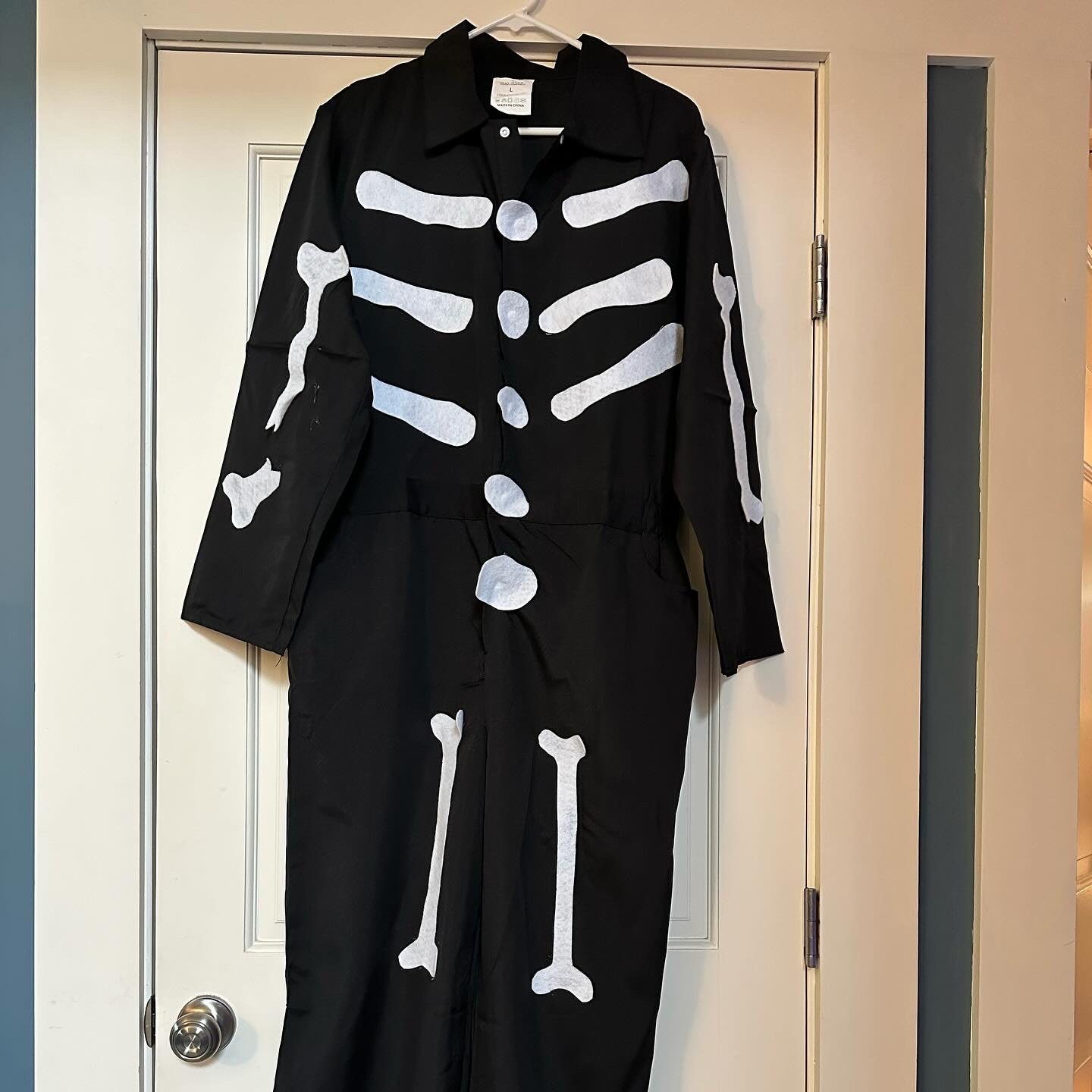

Costumes

Whether it’s Halloween in Salem or there’s costume ball happening within earshot, you can find me front and center with sketchbook, laptop and sewing machine at the ready! Whether it’s the defined space of a theme or the blue sky, open-ended land of “What do I feel like conjuring up in the land of textiles today…?”, the maker in me comes to life. Repurposing components, fabricating from a sketch or illustration or visually interpreting something to make it my own, I love a textile challenge….Can you tell?